technical parameter

-

Displacement (L)

2.122

-

Bore x Stroke (mm)

85.5x92.4

-

Compression Ratio

17:1

-

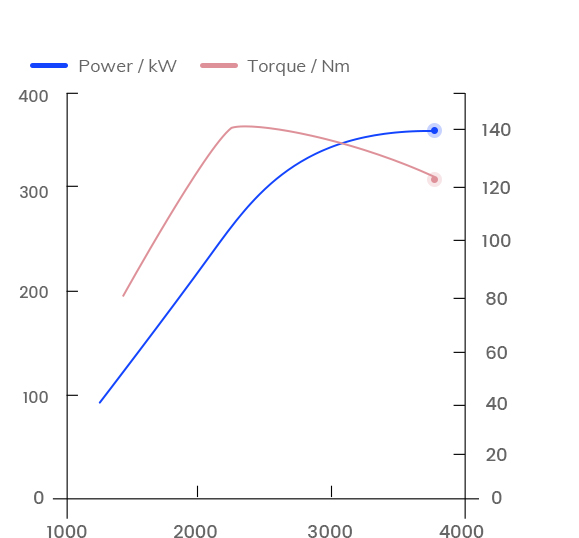

Max. Net Power /Speed (kW/rpm)

139/3887

-

Max. Net Torque /Speed (Nm/rpm)

370/2400

-

Specific Power (kW/L)

65.5

-

Dimension (mm)

620 x 860x 580

-

Weight (kg)

150

-

Emission

Diesel/ Jet Fuel

External characteristic curve

01

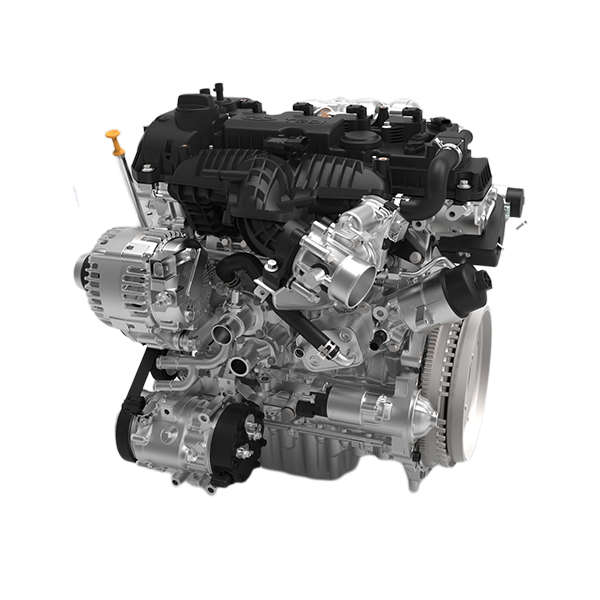

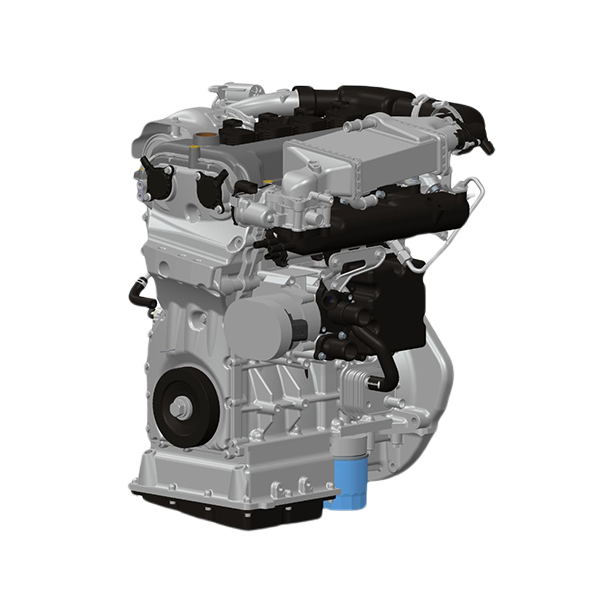

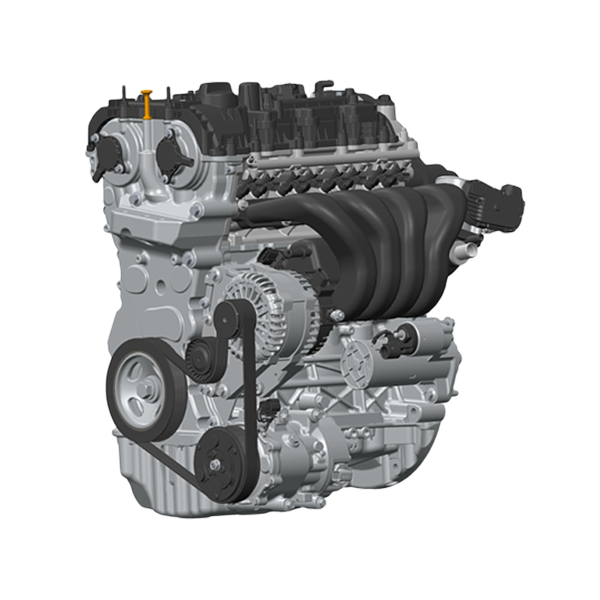

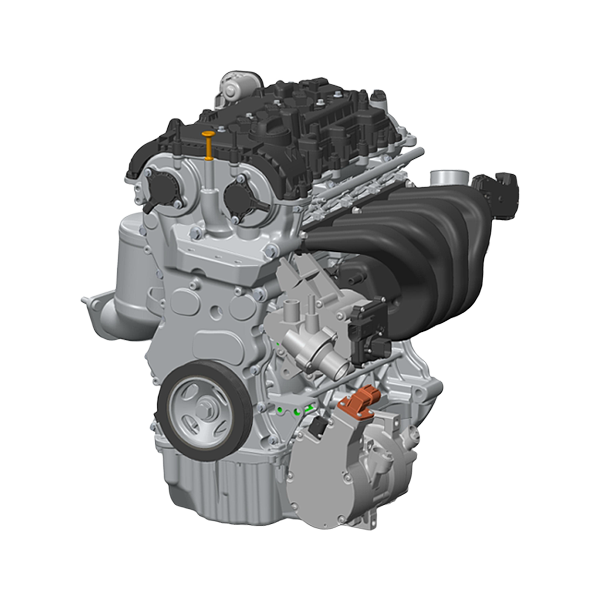

Key Technologies

Common Rail Direct Injection System with 1600bar High-pressure, Low Inertia Single-stage High-pressure Ratio Turbocharger, High-strength Lightweight Materials, High Swirl Ratio Combustion System, Dual Redundant Electronic Control System.

02

Extreme Performance

Achieving the maximum ground output power of 100 hp/L, the performance of 10000ft does not decay, and the continuous airworthiness at 20000ft.

03

Energy Saving and Environmental Protection

Compared with similar products, the fuel consumption is reduced by 10%, and the effective cruising range is increased by 10%.

04

Reliability and Durability

The integrated modular design, redundant design and the application of high-strength lightweight materials improve the reliability under all environmental conditions. TBO time can reach 2000h.

D4D20

The D4D20 engine adopts the latest high-efficiency combustion system + high-pressure common rail fuel injection system. The maximum net power is 139kW, the maximum output torque is 370Nm, and the fuel consumption is reduced by 10%, which can greatly increase the cruising range. The single-cylinder high-pressure common rail direct injection system independently and accurately corrects the fuel injection quantity, improves the working uniformity of each cylinder, reduces vibration, and has a high-pressure ratio turbocharger, which is more capable of adapting to high altitudes, and has no attenuation at 10,000ft altitude. The integrated modular design combined with high-strength and lightweight materials makes the engine lighter and more compact, and adopts technologies such as dual-redundant design of sensors and ECUs, high nickel-based valves, and the overhaul interval is as high as 2,000 hours.

D4D20

The D4D20 engine adopts the latest high-efficiency combustion system + high-pressure common rail fuel injection system. The maximum cruising power is 142kW, the maximum output torque is 370Nm, and the fuel consumption is reduced by 10%, which can greatly increase the cruising range. The single-cylinder high-pressure common rail direct injection system independently and accurately corrects the fuel injection quantity, improves the working uniformity of each cylinder, reduces vibration, and has a high-pressure ratio turbocharger, which is more capable of adapting to high altitudes, and has no attenuation at 10,000ft altitude. The integrated modular design combined with high-strength and lightweight materials makes the engine lighter and more compact, and adopts technologies such as dual-redundant design of sensors and ECUs, high nickel-based valves, and the overhaul interval is as high as 2,000 hours.