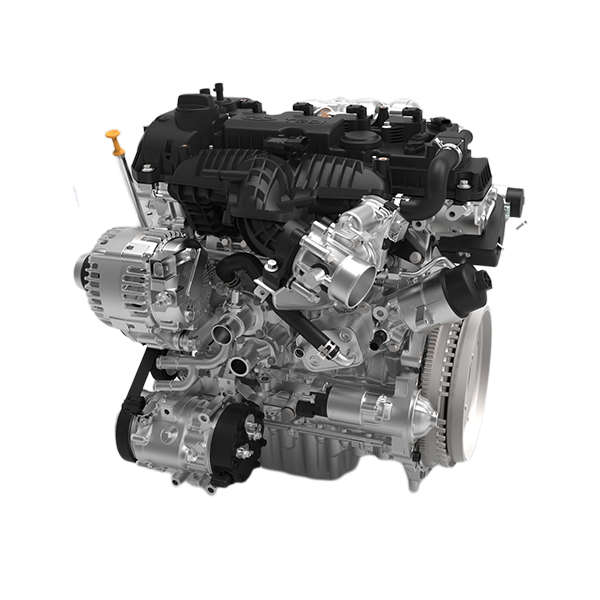

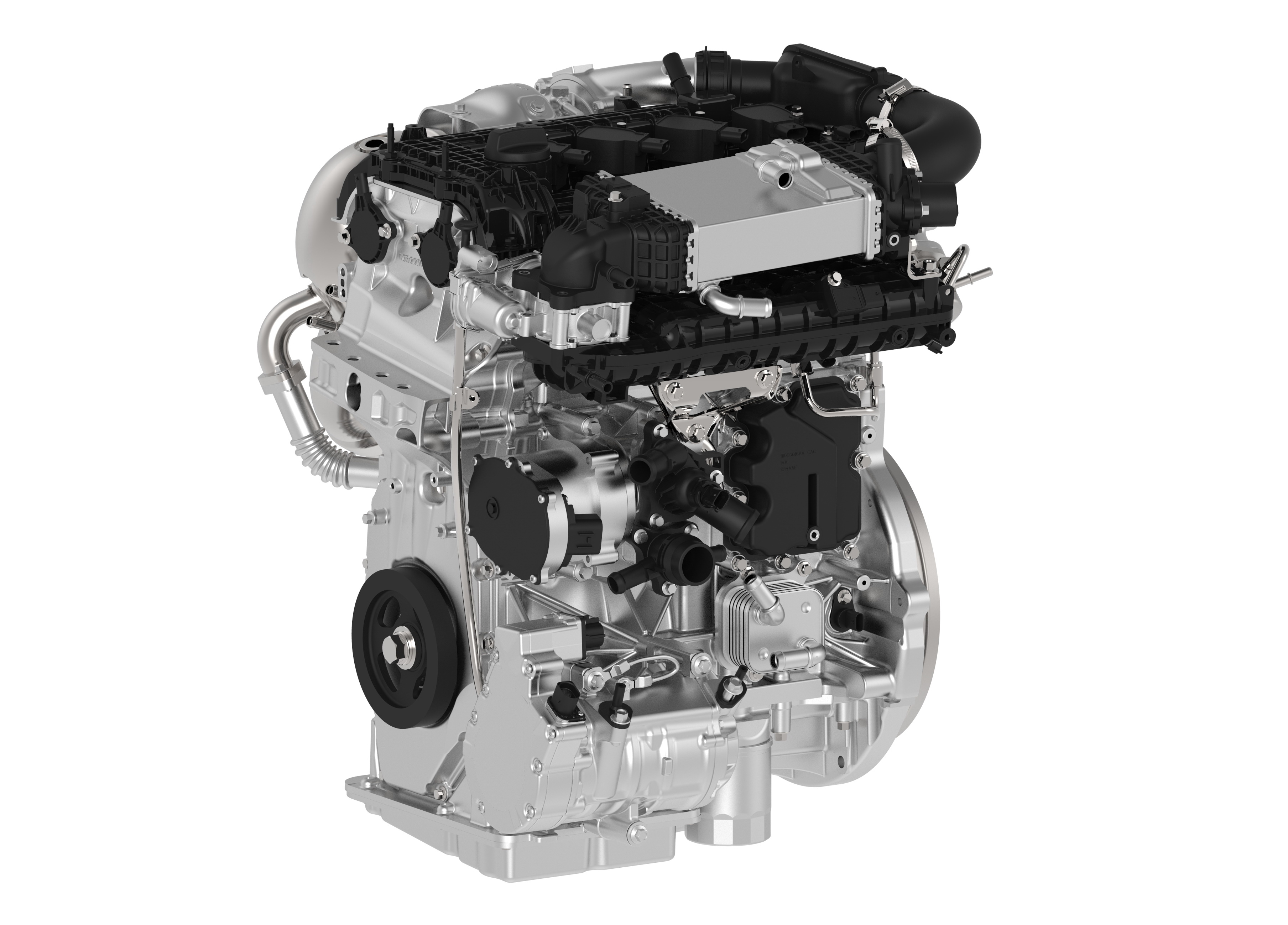

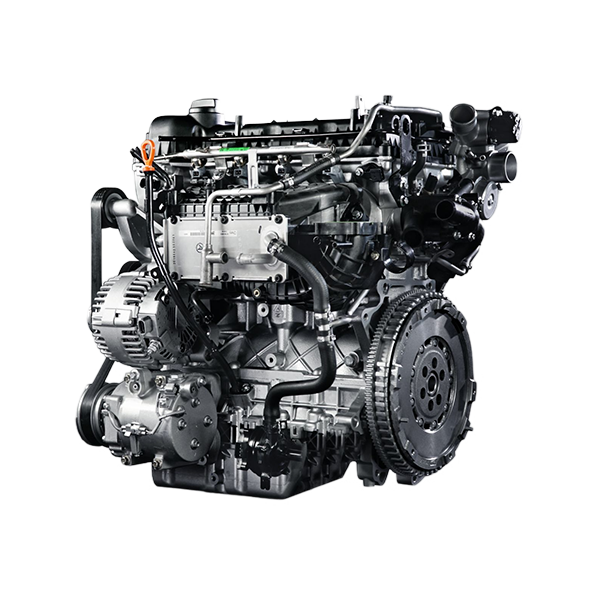

DHT125+E4T15C

Hybrid Power System For Hybrid, Extended-range and Plug-in Hybrid Vehicles

technical parameter

-

Max. Power of Engine (kW)

108

-

Max. Power of Engine (kW)

125

-

Max. Torque of Engine(Nm)

360

-

Total Torque of Motor(Nm)

440

-

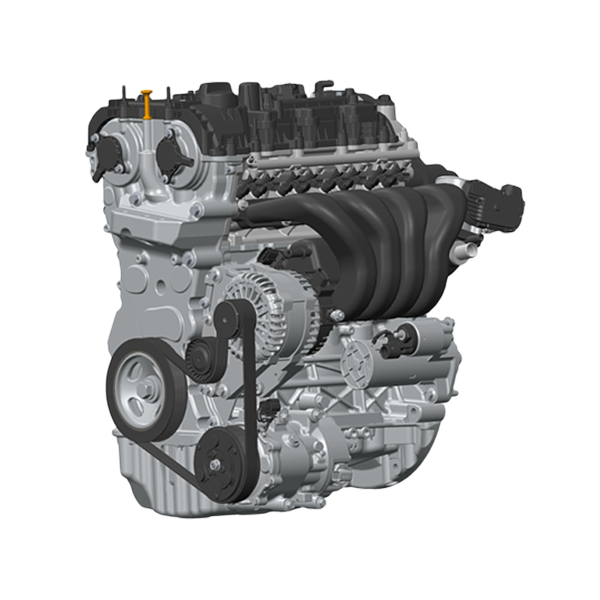

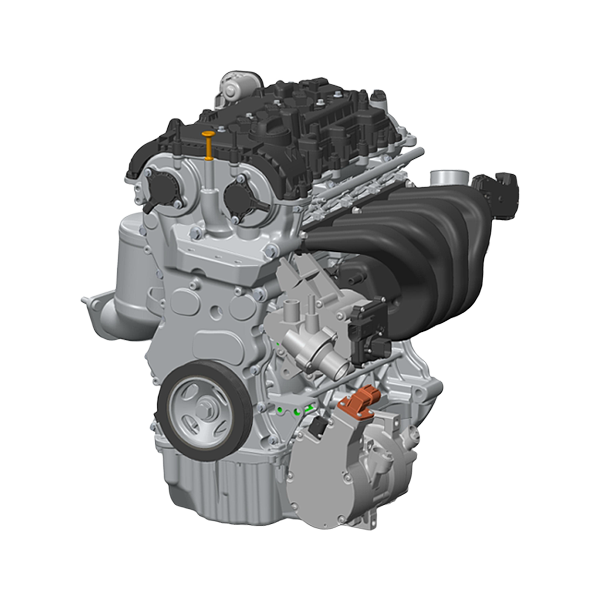

Engine

1.5 T

-

Motor (PS)

170

-

Transmission Case

DHT125

External characteristic curve

01

Key Technologies

With 11 gear combinations, applying dual-motor torque distribution technology, the power source works in the high-efficiency range; 2 motors can be driven independently or at the same time; dual-motor + DCT shifting technology; integrated design of MCU and transmission, no outlay high-voltage wiring harness; I-PIN flat wire motor technology, V-shaped magnetic steel/rotor skewed pole, excellent NVH performance; motor fixed-point jet fuel cooling technology.

02

Extreme Performance

Efficient Transmission, High Torque Output, Uninterrupted Power Shift.

03

Reliability and Durability

The motor performance requirements are reduced, the cost is lower, and the service life is longer. The MCU is highly integrated with the whole box, and the cost is low. It can be matched with multi-platform models.

04

Platform Development

A variety of working modes, which can be applied to hybrid, extended-range and plug-in hybrid vehicles.

E4T15C+DHT125

The E4T15C+DHT125 hybrid power system offers 11 speed modes. These again combine with the engines and operating modes to offer a range of application specific settings, while still allowing for individual variability for each driver. The 11 speeds cover all possible vehicle usage scenes, including low speed driving (for instance while moving in heavy traffic), long distance driving, mountain driving where low-end torque is welcome, overtaking, expressway driving, driving on slippery conditions, where the dual-axle motors will drive all four wheels for better traction, and urban commuting.

E4T15C+DHT125

In its production form, the hybrid system a combined system of 240 kW from the 2-wheel drive version and a staggering 338 kW combined power from the four-wheel drive system. The former has a tested 0-100 km acceleration time of less than 7 seconds and the latter dispenses of the 100 km acceleration run in 4 seconds.